How does NdFeB prevent corrosion?

Source: Tonghui Magnetoelectric Release date:2020-05-25 17:49 Views

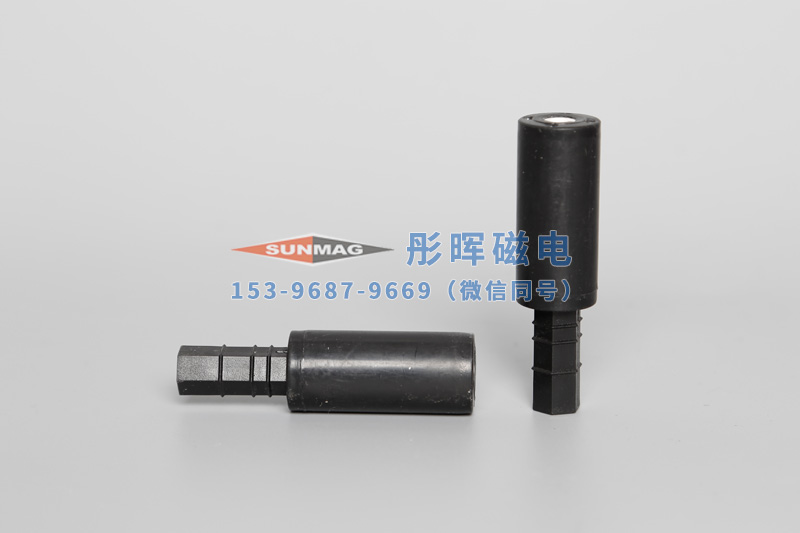

Corrosion is widely used in many industries, and naturally in the NdFeB industry is no exception, because NdFeB is easily corroded. Therefore, most finished products require electroplating or painting. Conventional surface treatments include nickel plating (nickel copper nickel), zinc plating, aluminum plating, electrophoresis, and the like. If working in a closed environment, phosphating can also be used.

NdFeB is a widely used and rapidly developing magnet product. NdFeB has been widely used since its invention, but it has not been used for more than 20 years. Due to its high magnetic properties and ease of processing, the price is not very high, so its application field is rapidly expanding. Currently, the commercial NdFeB magnetic energy product can reach 50 MW, which is 10 times that of ferrite.

Compared with other permanent magnet materials such as ferrite, NdFeB has excellent magnetic properties. Its magnetic energy products are much higher than other types of magnets, so it can be called the "first generation magnetic king". NdFeB has very high saturation magnetization BS (BS = 16KGS) and magnetic crystal anisotropy field HA (HA = 73KOE), neodymium magnet products are widely used in packaging, toys, gifts and crafts, fitness magnetron vehicles, motors , Micro motors, computers, instruments, meters, motorcycles, cameras, watches, sounds, household appliances, office automation, magnetic therapy and various fields of daily life.

NdFeB is also a powder metallurgy product, and its processing method is similar to samarium cobalt. At present, the maximum operating temperature of NdFeB is about 180 degrees Celsius. In the case of severe environmental applications, it is generally recommended not to exceed 140 degrees Celsius.

These are the NdFeB anticorrosion technologies we introduced in detail. Due to its high magnetic properties, neodymium iron boron is used to replace other magnetic materials in many occasions to reduce the volume of the product. If a ferrite magnet is used, the size of the current mobile phone may be smaller than half a brick.